Build ANSI Z358.1-2014 Compliant Labs in India with SbyD

Turnkey Solutions for Designing and Building Labs with ANSI Z358.1-2014 Emergency Equipment Compliance

ANSI Z358.1-2014 outlines stringent guidelines for emergency eyewash and shower equipment, ensuring laboratory personnel have immediate access to safety measures in case of exposure to hazardous substances. Compliance with this standard is critical for protecting health and maintaining safety in the workplace.

Looking to make your Labs ANSI Z358.1-2014 Compliant?

SbyD integrates ANSI Z358.1-2014-compliant emergency showers, eyewash stations, and related equipment into your laboratory design and build. Our turnkey solutions ensure your lab is equipped to meet safety standards and safeguard personnel effectively.

Key Aspects Covered Under ANSI Z358.1-2014 Guidelines

When designing and installing emergency eyewash stations and safety showers to meet ANSI Z358.1-2014 standards, several key aspects need to be addressed:

Proper Placement and Accessibility

Eyewash stations and safety showers must be installed within 10 seconds from the potential hazard area, ensuring immediate access in emergencies.

Water Flow and Temperature

Ensure eyewash stations provide 0.4 gallons per minute and safety showers 20 gallons per minute, with water temperature between 16°C to 38°C for effective decontamination.

Maintenance and Inspection

Regular testing, inspection, and maintenance schedules are essential to ensure that safety equipment remains fully operational and compliant with ANSI Z358.1-2014 standards.

Clear Labeling and Signage

Eyewash stations and safety showers must be clearly marked with visible signage to guide employees to the equipment in case of an emergency.

Training and Accessibility

Ensure regular training for staff on proper usage and accessibility of eyewash stations and safety showers, with clear, unblocked paths to the equipment.

Consequences of Not Being ANSI Z358.1-2014 Compliant

Facilities that are not compliant with ANSI Z358.1-2014 face several significant challenges:

- Increased Risk of Injury: Improperly designed or unmaintained emergency equipment can result in delays in providing crucial decontamination, leading to more severe injuries.

- Legal and Regulatory Consequences: Failure to comply with ANSI Z358.1-2014 may result in penalties, fines, or legal actions for not meeting workplace safety standards.

- Loss of Business and Reputation: Non-compliance can damage a facility’s reputation, particularly with clients and stakeholders who prioritize worker safety.

Why Choose SbyD for ANSI Z358.1-2014 Compliant Safety Equipment?

At SbyD, we offer more than just consultancy for ANSI Z358.1-2014 compliance. Our expertise in turnkey design, installation, and ongoing maintenance services ensures that your eyewash stations and safety showers are always up to standard. From initial planning and design to installation and periodic testing, we provide a seamless solution to meet all ANSI Z358.1-2014 requirements, ensuring a safe working environment for your team.

Checkout our Project Gallery

Turnkey Case Studies

Explore our detailed case studies that showcase how our innovative, NABL-compliant lab solutions have transformed various industries. From concept to completion, discover how we navigate complex challenges, implement solutions adhering to both Indian and global standards, and deliver successful, safe, and compliant outcomes.

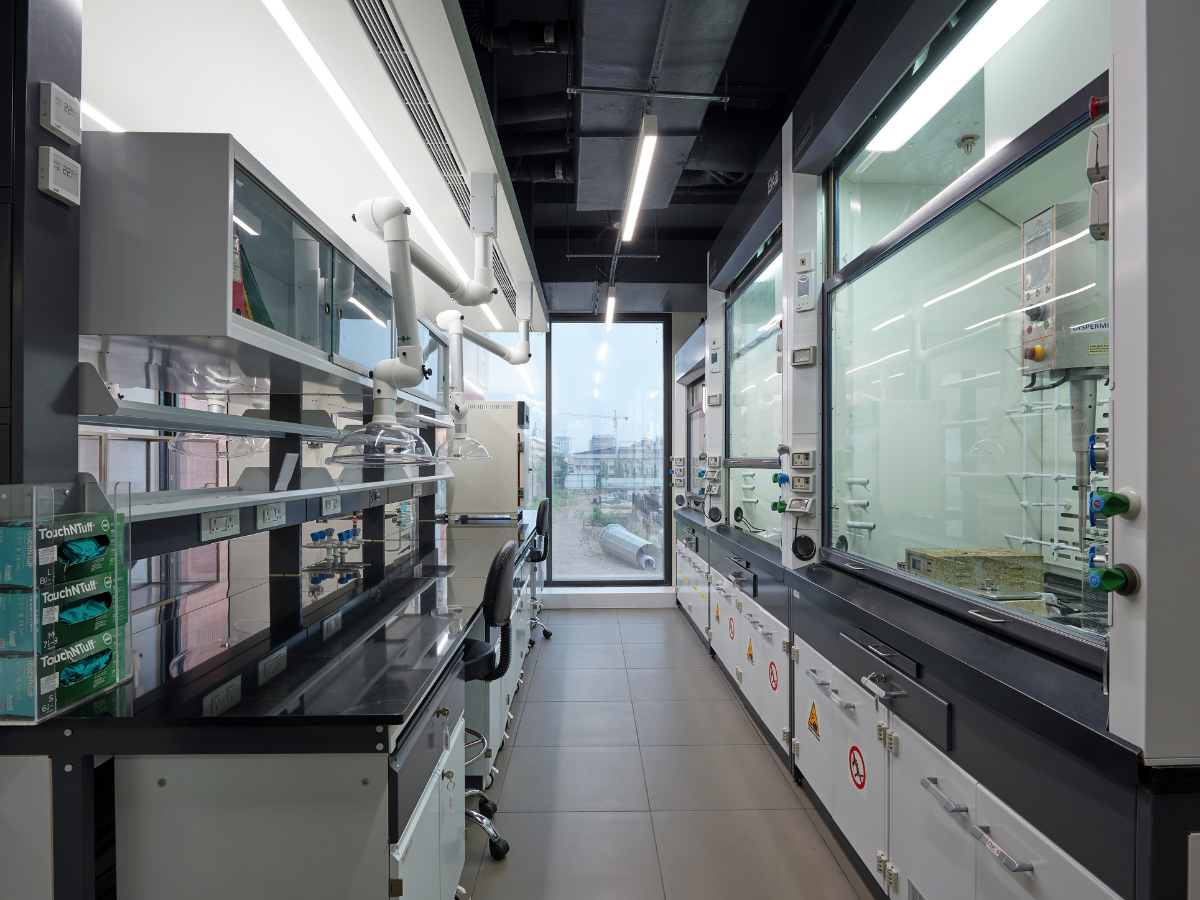

Turnkey Lab Project Gallery

Browse through our extensive Lab Project Gallery to see our NABL-compliant work in action. Each project demonstrates our commitment to quality, safety, and adherence to a wide range of Indian and global standards in laboratory design and construction, ensuring not just compliance but exceeding safety benchmarks.

Turnkey Lab Office Project Gallery

Our Lab Office Project Gallery highlights the blend of functionality, aesthetics, and compliance. We design spaces that boost productivity while strictly adhering to NABL and other international safety standards, ensuring a compliant and safe work environment.